Accuracy Custom 3 axis CNC Machining Service For High Performance Products

-

Highlight

Accuracy Custom CNC Machining Service

,3 Axis CNC Machining Service

-

CNC Machine3-axis, 4-axis, 5-axis

-

Processing Accuracy0.005mm

-

CNC Machine Control SystemFANUC, Siemens, Mitsubishi, Etc.

-

DetectionWe Will 100% Inspect The Products Before Shipment

-

Surface roughnessRa0.4~3.2

-

MaterialStainless Steel, Titanium Alloy, Aluminum, Iron, Copper, Steel, PP, PPSU, POM, Nylon, PEEK, Acrylic, Etc

-

ColorCustomized

-

Surface TreatmentAnodize, Sandblasting, Heat Treatment, Polishing, Powder Coating, Electroplating, Etc.

-

Place of OriginDongguan, China

-

Brand NameRenjie Precision

-

CertificationISO9001,ISO13485

-

Minimum Order QuantityOne piece

-

PriceQuotation as required

-

Packaging DetailsWaterproof and collision

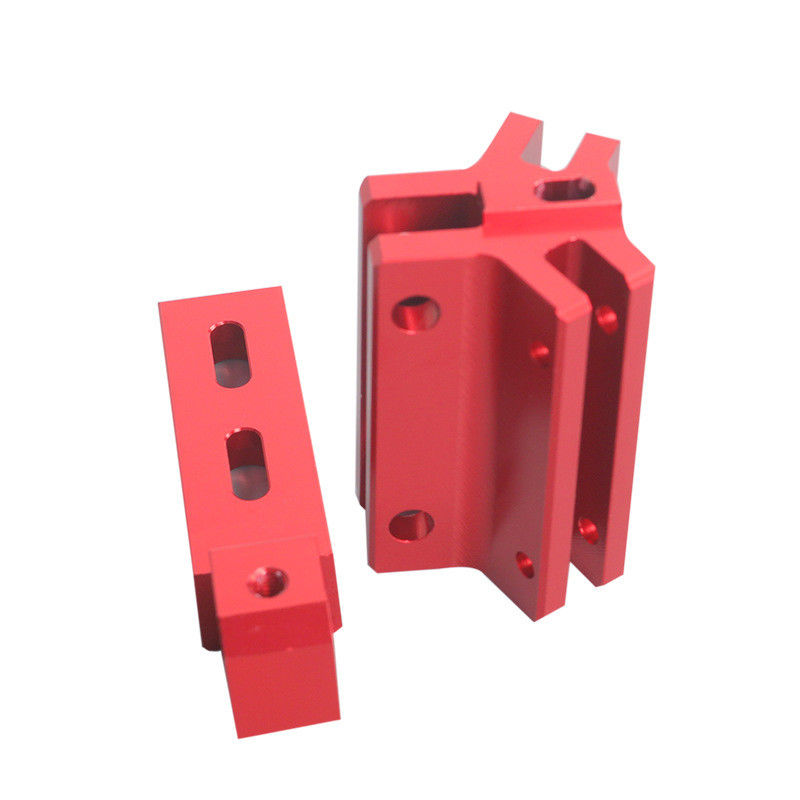

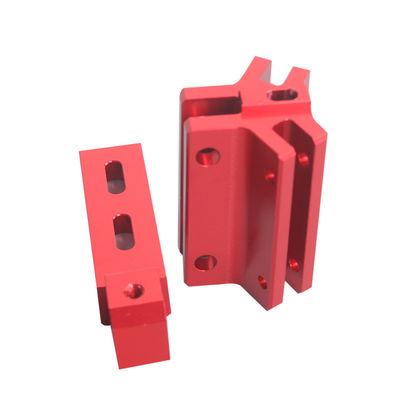

Accuracy Custom 3 axis CNC Machining Service For High Performance Products

Processing Accuracy Custom CNC Machining Service For High-Performance Products

Product Description:

Medical CNC Machining is a cutting-edge product that offers precision manufacturing services for medical devices. With advanced CNC Machine technology and a variety of surface treatment options, this product is perfect for medical device manufacturing.

- 3-axis, 4-axis, and 5-axis CNC Machines

- Capable of precision CNC Nylon Machining and Automotive CNC Machining Services

- Utilizes state-of-the-art CNC Milling Machine technology

- Anodize

- Sandblasting

- Heat Treatment

- Polishing

- Powder Coating

- Electroplating

- And more

We understand the importance of quality control in the medical industry, which is why we have a rigorous detection process in place. Before shipment, we guarantee to 100% inspect all products to ensure they meet our high standards of precision and quality.

Our CNC Machines are capable of achieving a surface roughness of Ra0.4~3.2, ensuring a smooth and flawless finish for all medical devices.

We use top-of-the-line CNC Machine control systems, including FANUC, Siemens, Mitsubishi, and more, to ensure the highest level of precision and accuracy in our manufacturing process.

- State-of-the-art CNC Machines for precision manufacturing

- Wide range of surface treatment options for customizable finishes

- Rigorous detection process for quality assurance

- High surface roughness capabilities for a smooth finish

- Top-quality CNC Machine control systems for precision and accuracy

Medical CNC Machining is the ideal solution for all your medical device manufacturing needs. With advanced CNC Machine technology, a variety of surface treatment options, and a commitment to quality control, we guarantee the highest level of precision and accuracy for all your medical devices. Choose Medical CNC Machining for top-quality results.

![]()

![]()

Features:

- Product Name: Medical CNC Machining

- Surface Treatment:

- Anodize

- Sandblasting

- Heat Treatment

- Polishing

- Powder Coating

- Electroplating

- Etc.

- CNC Machine:

- 3-axis

- 4-axis

- 5-axis

- Detection: We Will 100% Inspect The Products Before Shipment

- CNC Machine Control System:

- FANUC

- Siemens

- Mitsubishi

- Etc.

- Surface Roughness: Ra0.4~3.2

- Key Features:

- CNC Milling Tool

- Automotive CNC Machining Services

- CNC Plastic Machining

- Precision Machined Components

Technical Parameters:

| Features | Specifications |

|---|---|

| CNC Parts Machining | 3-axis, 4-axis, 5-axis CNC machines Processing accuracy of 0.005mm Materials: Stainless Steel, Titanium Alloy, Aluminum, Iron, Copper, Steel, PP, PPSU, POM, Nylon, PEEK, Acrylic, Etc |

| Custom CNC Machining Service | Surface roughness: Ra0.4~3.2 Surface treatment options: Anodize, Sandblasting, Heat Treatment, Polishing, Powder Coating, Electroplating, Etc. CNC Machine control system: FANUC, Siemens, Mitsubishi, Etc. 100% inspection of products before shipment |

| CNC Machining Parts | Customized color options Suitable for medical use Durable and precise Wide range of material options |

Applications:

Renjie Precision is a leading manufacturer of high-quality medical CNC machining parts and services. Our company is located in Dongguan, China and we have been certified with ISO9001 and ISO13485 for our exceptional quality management systems. With a minimum order quantity of one piece and competitive pricing, we are dedicated to providing customized solutions for our clients in the medical industry.

Our medical CNC machining parts and services are widely used in the manufacturing of medical equipment. With our advanced technology and precision machining, we are able to produce high-quality parts that meet the strict requirements of the medical industry. Our products are suitable for a variety of medical applications.

Our products are also widely used in medical research and development, as well as in the production of custom medical equipment. Our CNC milling machines allow us to create complex and precise parts, making them ideal for customized designs and prototypes.

At Renjie Precision, we understand the critical importance of precision in the medical industry. That's why we use state-of-the-art CNC machines and control systems to achieve an accuracy of 0.005mm in our products. This level of precision ensures that our parts meet the strict requirements of medical equipment and contribute to the overall safety and effectiveness of medical procedures.

We use a wide range of high-quality materials to manufacture our medical CNC machining parts, including stainless steel, titanium alloy, aluminum, iron, copper, and more. These materials are carefully selected to meet the specific needs of each medical application, ensuring durability, corrosion resistance, and biocompatibility.

We understand that every medical application is unique and may require customized solutions. That's why we offer customized design services to meet the specific requirements of our clients. Our professional team works closely with our clients to understand their needs and provide the best possible solutions.

At Renjie Precision, we continuously invest in the latest technology and equipment to stay at the forefront of the medical CNC machining industry. Our CNC machines are equipped with FANUC, Siemens, and Mitsubishi control systems, providing precise and efficient machining for our products.

![]()

![]()

Customization:

Brand Name: Renjie Precision

Place of Origin: Dongguan, China

Certification: ISO9001,ISO13485

Minimum Order Quantity: One piece

Price: Quotation as required

Packaging Details: Waterproof and collision

Color: Customized

Surface Treatment: Anodize, Sandblasting, Heat Treatment, Polishing, Powder Coating, Electroplating, Etc.

CNC Machine Control System: FANUC, Siemens, Mitsubishi, Etc.

CNC Machine: 3-axis, 4-axis, 5-axis

Processing Accuracy: 0.005mm

At Renjie Precision, we offer specialized Custom CNC Machining Services for Medical Equipment Parts. Our state-of-the-art CNC machines, equipped with FANUC, Siemens, Mitsubishi, and other high-quality control systems, allow us to provide high precision and accurate parts for your medical equipment needs.

We understand the critical importance of precision and quality in the medical industry, which is why we have obtained ISO9001 and ISO13485 certifications. With our advanced CNC machining technology and experienced team, we can provide customized solutions to meet your specific requirements.

Our CNC machining parts undergo various surface treatments such as anodizing, sandblasting, heat treatment, polishing, powder coating, and electroplating to ensure durability and resistance to wear and tear. We also offer a wide range of colors to choose from for a more personalized touch.

Our minimum order quantity is only one piece, making it convenient for you to test our services and products before placing a larger order. Our prices are quoted as per your specific requirements, ensuring that you get the best value for your money.

For safe and secure delivery, our packaging is waterproof and can withstand collisions during transportation. With our CNC machines capable of 3-axis, 4-axis, and 5-axis machining, we guarantee a processing accuracy of 0.005mm for all your medical equipment parts.

Choose Renjie Precision for all your Custom CNC Machining needs and experience the highest quality and precision in every part we produce. Contact us now to get a quote for your project!