Accuracy Cnc Milling Titanium Polished Anodized Parts For Aerospace Application

-

Highlight

Anodized cnc milling Parts

,Polished cnc milling Parts

,titanium cnc milling Parts

-

ApplicationMedical, Aerospace, Automotive, Etc.

-

DeliveryDHL, UPS, FedEx, Etc.

-

EquipmentCNC Lathe, Milling Machine, Drilling Machine, Etc.

-

Tolerance±0.01mm

-

ProcessCNC Machining

-

AccuracyHigh

-

Surface TreatmentPolishing, Anodizing, Sandblasting, Etc.

-

MaterialStainless Steel, Titanium Alloy, Aluminum, Iron, Copper, Steel, PP, PPSU, POM, Nylon, PEEK, Acrylic, Etc

-

Place of OriginDongguan, China

-

Brand NameRenjie Precision

-

CertificationISO9001,ISO13485

-

Minimum Order QuantityOne piece

-

PriceQuotation as required

-

Packaging DetailsWaterproof and collision

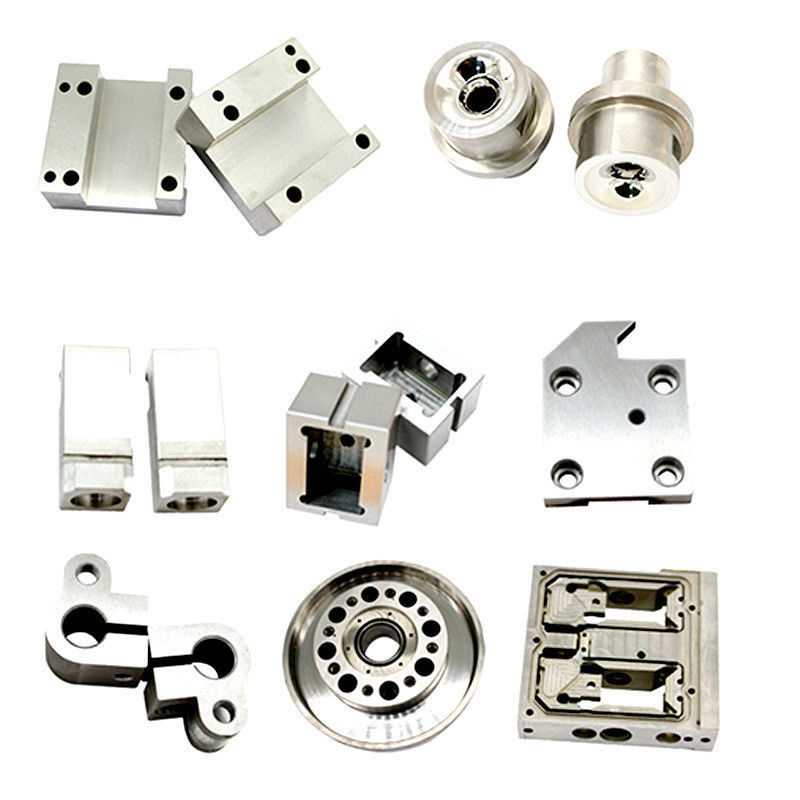

Accuracy Cnc Milling Titanium Polished Anodized Parts For Aerospace Application

Product Description:

The realm of precision engineering has been revolutionized by the advent of CNC (Computer Numerical Control) machining, and when it comes to high-strength, lightweight, and precision-crafted components, Titanium CNC Machining stands at the forefront. This product is the epitome of engineering excellence, combining state-of-the-art CNC technology with the exceptional qualities of various materials, including stainless steel, titanium alloy, aluminum, iron, copper, steel, and a range of plastics such as PP, PPSU, POM, Nylon, PEEK, and Acrylic. Our Titanium CNC Machining service is tailored to meet the needs of industries where precision is non-negotiable.

At the heart of our Titanium CNC Machining product is the commitment to unparalleled precision. With a tolerance of ±0.01mm, our CNC parts machining process ensures that each component is crafted with the utmost accuracy. This high level of precision is critical in applications where even the slightest deviation could lead to failure of the entire system. Our clients can rest assured that each part we manufacture meets their exact specifications, thereby guaranteeing the reliability and performance of their products.

The materials we use in our Titanium CNC Machining service are chosen for their durability and performance characteristics. Stainless steel and titanium alloy are known for their strength and corrosion resistance, making them ideal for aerospace, medical, and automotive applications. Aluminum CNC machining brings forth lightweight yet sturdy components widely used in various industries, from electronics to construction. Iron and copper provide robust alternatives with distinct properties, such as superior thermal and electrical conductivity in the case of copper. Furthermore, our selection of plastics like PEEK and Acrylic allows for the creation of parts that require specific non-metallic properties such as insulating capabilities or transparency.

![]()

Our process harnesses the advanced capabilities of CNC machining to carve out precise components from these diverse materials. CNC parts machining is a subtractive manufacturing process where the material block is meticulously cut into the desired shape using computer-controlled milling, turning, or drilling machines. This process offers repeatability, efficiency, and the ability to produce complex geometries that would be difficult or impossible to achieve with manual machining.

To ensure that every part we deliver is of the highest quality, we have instituted a rigorous inspection protocol. Every component undergoes 100% inspection before shipment, utilizing various methods to verify dimensions, surface finish, and material properties. This unwavering commitment to quality assurance means that our clients receive products that are not only dimensionally accurate but also free from defects and ready to perform in their intended applications.

The aesthetics and functionality of machined parts are often as important as their technical specifications, which is why we offer a variety of surface treatments. Our parts can be finished with polishing to achieve a mirror-like appearance, anodizing to enhance corrosion resistance and aesthetic appeal, or sandblasting to create a uniform, matte surface. These treatments not only improve the visual and tactile qualities of the parts but can also extend their service life by providing additional protection against environmental factors.

In conclusion, our Titanium CNC Machining product offers a superior solution for clients requiring high-precision, durable components manufactured from a range of materials. With our advanced CNC parts machining capabilities, stringent quality controls, and comprehensive surface treatment options, we provide a product that stands up to the demands of even the most critical applications. Whether it's for aerospace, medical, automotive, or any other industry, our Titanium CNC Machining service is the reliable choice for premium CNC machined parts.

Features:

- Product Name: Titanium CNC Machining

- Surface Treatment: Polishing, Anodizing, Sandblasting, etc.

- Inspection: 100% Inspection before shipment

- Tolerance: ±0.01mm

- Package: Standard export package

- Accuracy: High

- Keywords: CNC Parts Machining

- Keywords: cnc milling titanium

- Keywords: CNC Machining Components

Technical Parameters:

| Attribute | Details |

|---|---|

| Material | Stainless Steel, Titanium Alloy, Aluminum, Iron, Copper, Steel, PP, PPSU, POM, Nylon, PEEK, Acrylic, Etc |

| Process | CNC Machining |

| Delivery | DHL, UPS, FedEx, Etc. |

| Surface Treatment | Polishing, Anodizing, Sandblasting, Etc. |

| Application | Medical, Aerospace, Automotive, Etc. |

| Roughness | Ra 0.4~3.2 |

| Package | Standard Export Package |

| Equipment | CNC Lathe, Milling Machine, Drilling Machine, Etc. |

| Accuracy | High |

| Inspection | 100% Inspection Before Shipment |

![]()

![]()

Applications:

Renjie Precision, headquartered in Dongguan, China, is a recognized leader in the field of CNC machining components. Our Titanium CNC Machining product stands as a testament to our commitment to quality and precision. With certifications such as ISO9001 and ISO13485, we ensure that every component we produce meets the highest standards of quality and reliability. Our process includes the utilization of sophisticated equipment such as CNC lathes, milling machines, and drilling machines, which allow us to achieve surface roughness (Ra) ranging from 0.4 to 3.2, catering to diverse industry needs.

As we understand the critical nature of CNC parts machining in various applications, Renjie Precision offers a minimum order quantity of just one piece, making it accessible for prototypes and small batch production. Clients can request a quotation as required, ensuring that pricing is transparent and tailored to their specific project requirements. Our packaging details exemplify our commitment to product integrity, with waterproof and collision-resistant materials ensuring that your order arrives in impeccable condition.

The inspection process is rigorous, with 100% inspection before shipment to guarantee that each CNC machining component adheres to the exact specifications provided by our clients. For delivery, we utilize a standard export package, which provides additional security and peace of mind during transit. The applications and scenarios for our Titanium CNC Machining products are vast, ranging from aerospace, where the strength-to-weight ratio and corrosion resistance of titanium are crucial, to the medical industry, where non-reactivity and biocompatibility are of paramount importance.

Other industries that benefit from our CNC machining components include automotive, where durability and performance are enhanced; marine, where the material's resistance to saltwater corrosion is essential; and high-performance engineering sectors, where precision and longevity of components are key. Whether you are developing cutting-edge equipment or looking to innovate within your field, Renjie Precision's Titanium CNC Machining services offer the reliability and quality that your projects demand.

![]()

![]()

Customization:

Brand Name: Renjie Precision

Place of Origin: Dongguan, China

Certification: ISO9001, ISO13485

Minimum Order Quantity: One piece

Price: Quotation as required

Packaging Details: Waterproof and collision-proof packaging ensures the safety of your components during transport.

Package: Standard Export Package

Process: CNC Machining - Our state-of-the-art CNC Machining Center is equipped to handle even the most Complex CNC Machining tasks with precision.

Roughness: Ra 0.4~3.2 - We can achieve a fine finish and precise dimensions on all machined parts.

Surface Treatment: Includes options such as Polishing, Anodizing, and Sandblasting, among others, to enhance the appearance and performance of your components.

Material: We work with a diverse range of materials, including Stainless Steel, Titanium Alloy, Aluminum, Iron, Copper, Steel, PP, PPSU, POM, Nylon, PEEK, Acrylic, etc., to meet the specifications of your project.

We specialize in both CNC Metal Machining and CNC Plastic Machining, delivering custom solutions tailored to your unique needs.

Support and Services:

Our Titanium CNC Machining product comes with comprehensive technical support and services designed to ensure maximum uptime and optimal performance. Our team of experienced engineers and technicians are available to provide expert guidance and troubleshooting assistance for any issues that may arise during the use of our product.

We offer a variety of services including:

- Installation and setup assistance to ensure your CNC machine is operational and configured according to your specific requirements.

- On-demand technical support to help diagnose and resolve unexpected problems or to optimize machine performance.

- Regular maintenance checks and service updates to keep your machine running at peak efficiency and to extend its lifespan.

- Training sessions for your staff to ensure they are fully equipped to operate the machinery safely and effectively.

- Replacement parts and repair services for any components that may wear out or need attention over time.

Our commitment to customer satisfaction means that our support extends beyond just addressing technical issues. We also provide advice on best practices for titanium machining, helping you to achieve the best possible results with our product.

Please note that our technical support and services are available during regular business hours and we endeavor to respond to all inquiries promptly. We are dedicated to providing a high level of service to all our customers to ensure your operations are not just maintained, but continuously improved with our Titanium CNC Machining solution.